Redefining

Palm Oil

Efficiency

technology

practices

expertise

Transforming Palm Oil Milling Through Innovation

Company Snapshot

Transforming palm oil milling since 1992 through automation and optimization.

- Founded in 1992

- 20+ years expertise

- Strong R&D focus

- Experienced engineers

- Sustainable solutions

Novel HEMS Technology

Patented system enhancing efficiency, yield, and sustainability.

- Patent MY-208587-A

- Boosts CPO yield

- Optimizes steam use

- Reduces waste

- Enhances process flow

Why Novel Dynamics?

Local innovation driving sustainable mill performance.

- 100% Malaysian-made

- Energy-efficient

- Eco-focused design

- Tailored for each mill

- Continuous R&D growth

Smarter processes, higher yields & faster ROI, powered by efficiency, innovation, precision, and growth.

Operation Hour

Our operations run from Monday to Saturday, and you may contact us during this period. Let’s connect now.

- Mon > 8:30 AM – 5:30 PM

- Tue > 8:30 AM – 5:30 PM

- Wed > 8:30 AM – 5:30 PM

- Thu > 8:30 AM – 5:30 PM

- Fri > 8:30 AM – 5:30 PM

- Sat > Closed

- Sun > Closed

Contact us

Have a question? Don’t hesitate we’d love to hear from you. Let’s start the conversation today!

Transport

Proven Technology Increasing OER and Palm Oil Profitability

Novel HEMS is designed to transform the core operations of palm oil mills. By focusing on sterilising and threshing, we help mills achieve higher output, lower costs, and sustainable profitability.

Maximizing Benefits with Novel HEMS

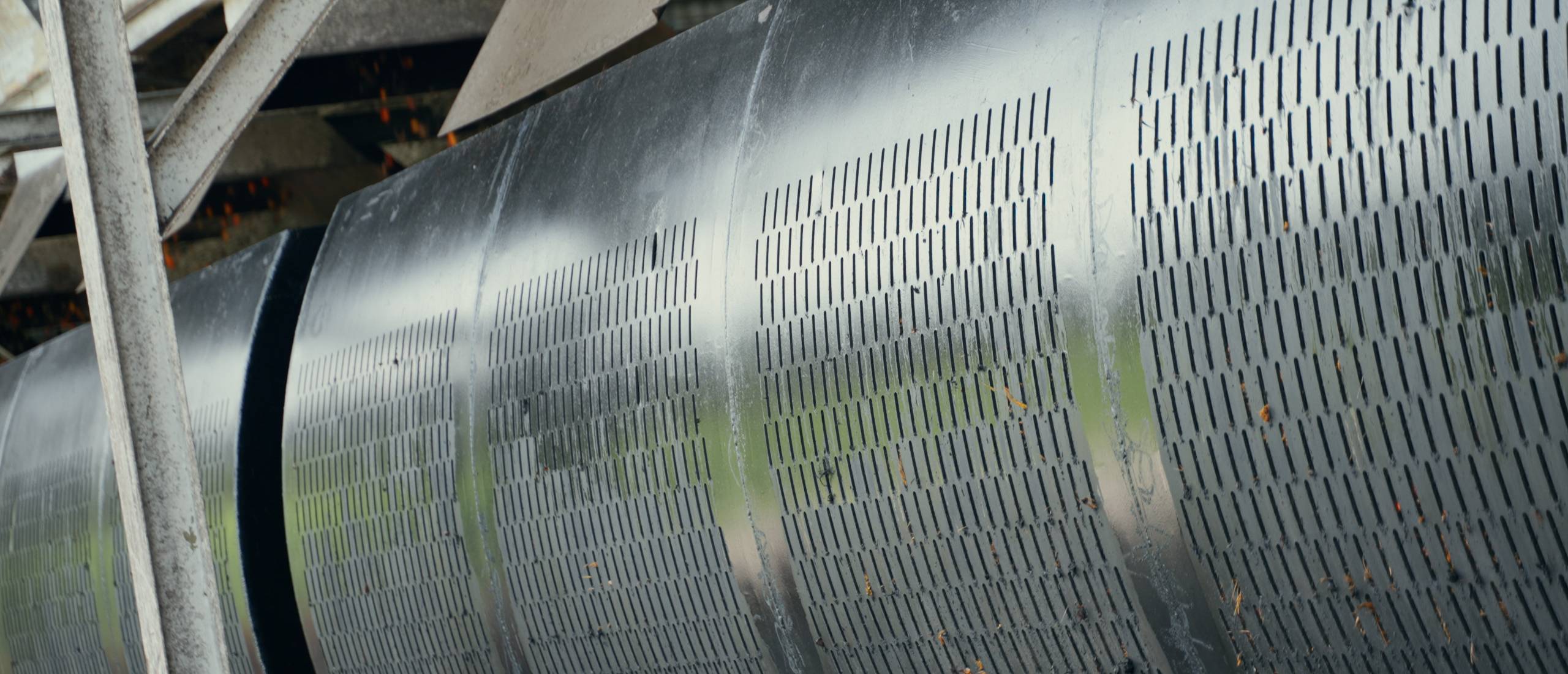

What are the benefits of the Novel HEMS System in palm oil extraction?

The performance of the “Novel HEMS” System in sterilization directly impacts several critical outcomes in palm oil extraction, including maximizing sterilization efficiency, shortening sterilization time, ensuring uniform heat distribution, optimizing steam management, improving heat penetration, reducing steam consumption, and enhancing overall product quality.

How does the performance of the Novel HEMS FFB Cages contribute to mill efficiency?

The “Novel HEMS” FFB cages enhance mill efficiency and oil quality by ensuring proper fruit bunch positioning and sufficient steam circulation for uniform sterilization, halting enzymatic activity, and loosening oil-bearing cells. Key indicators include maximizing sterilization efficiency, shortening sterilization time to preserve carotenoids for a higher DOBI value, and ensuring even heat distribution.

What role does uniform heat distribution play in the Novel HEMS FFB Cages?

Uniform heat distribution is critical and is achieved using “Novel HEMS” steam distribution systems and cages with optimized perforation patterns, ensuring consistent sterilization results across all fruit bunches.

What are the benefits of the Novel HEMS Steam Management System?

The “Novel HEMS” Steam Management System optimizes steam usage through effective monitoring and control, ensuring efficient, safe, and cost-effective operations with a design that includes balanced flow and pressure controls to enhance performance.

How does the Novel HEMS Sterilizer Steam Distribution improve the process?

The innovative “Novel HEMS” Steam Distribution design improves heat penetration, achieves more even heat distribution, and reduces steam consumption, contributing to enhanced sterilization efficiency and higher product quality.

What are the advantages of the Novel HEMS Sterilizer Automation System?

The “Novel HEMS” Sterilizer Automation System improves the sterilizer recipe, enhances operational efficiency, and boosts oil quality by optimizing air removal during sterilization, ensuring efficient steam use, minimizing waste, and enabling even steam penetration into fruit bunches.